Grain-size distribution

Grain-size distribution is of great importance for the mechanical properties for a soil and for the selection of compaction equipment.

The grain-size distribution is determined by a sieve test and a sedimentation test if necessary. Ocular analysis can also be used to categorize coarse-grained soil.

Gradation

Gradation is an important factor for bearing capacity and for the compaction and is determined from the grain-size distribution curve.

Cu=d60/d10 where d60 and d10 are the particle diameters corresponding to values of 60 and 10 percent on the grain-size distribution curve.

If Cu is less than 5 the soil is considered uniformly graded and if Cu is greater than 15 the soil is considered well-graded. In between these two, the soil is medium-graded. The limits differ from one classification system to another.

In well-graded material, represented by a curve covering a full range of grain-sizes, the voids left by the large particles are filled by the smaller ones. This results in a dense structure and good load bearing capacity.

A curve showing grains of more or less the same size indicates a uniformly graded material. In this case, there are no smaller particles to fill the voids. Consequently, it is harder to achieve a high density and bearing capacity in uniformly graded material than in well-graded material.

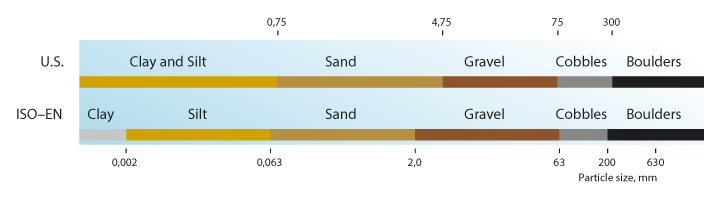

Classification of soil types

Soils can also be generally classified in larger groups, for example, as coarse-grained or fine-grained, granular or non-granular and cohesive or non-cohesive soils.

There are no general rules that govern the permitted maximum content of fines in coarse-grained and granular types of soils. Values vary between 15-50% depending on the classification system. A coarse grained soil is generally regarded as free-draining if it contains a maximum of 5-10% fines (silt and clay).

Resistance to compaction

There are three types of resistance to compaction in a soil: friction, cohesion and apparent cohesion.

Friction is caused by the interaction between the particles and is the main resistance in a coarse-grained soil.

Cohesion is caused by molecular forces between the smallest particles and constitutes the main source of resistance in a fine-grained soil.

Apparent cohesion is caused by the capillary forces of the water in the soil and occurs more or less in all soils. If water is added, the water will finally also act as a lubricant between the soil particles.

Most soils attain their highest dry density at a certain optimum water content for a given compaction effort. In simple terms, a soil with water content below the optimum requires more compaction effort to reach the same density as soil at optimum water content, whereas a wet soil is soft and easier to compact. The highest dry density is obtained at the optimum water content, between the wet and dry states. The most common method for determining this state is the Proctor test.

Clean sand and gravel, as well as other free-draining coarse materials, are less sensitive to variations in water content, and can attain maximum density in a completely dry or in a water-saturated state as long as the internal resistance to compaction is overcome during the compaction process.

Laboratory compaction tests

The optimum water content can be determined in a laboratory compaction test. There are two basic types of laboratory compaction test. One employs a standard weight falling onto a soil sample in a mold; the other is a standardized vibro-compaction test.

The most common method is the Proctor test which relies on a falling weight. The Proctor test is recognized as the most common laboratory method for determining the relationship between density and water content. The test establishes the optimum water content for a soil as well as the reference density. The density is expressed as dry density, which is the ratio between the weight of the dried soil particles and the volume of the sample.

Proctor test

A sample of the soil to be tested is placed in a cylindrical mould and compacted with a falling weight. Maximum particle size is limited to one-tenth of the diameter of the mould. If there is a low percentage of large particles, the maximum particle size is limited to one-fifth of the diameter of the mould. The size of the mold is 4” (102 mm), and 6” (153 mm) for larger particles.

The Proctor test can be carried out in one of the variants known as Standard and Modified Proctor. The compaction effort is 4,5 times greater for Modified Proctor than Standard.