Canals

Canals have to be designed and built to withstand enormous water pressure. In addition, they have to be watertight so that they will not leak and they have to be able offer protection from the risk of erosion caused by the flowing water.

The bottom of the canal is levelled off and compacted. A filter layer consisting of sand and gravel is then put in place and, on top of that, a sealing layer of fine soil, cement or asphalt. There is always a certain amount of leakage through the sealant and the filter ensures that the sealant does not get washed away. If fine soil is used as the sealing layer, it must be covered by an erosion resistant layer. It is highly important that the various layers are correctly compacted to avoid cracks in the sealing layer.

Earth dams

There are certain similarities between the functional properties of canals and earth dams, but they are built in different ways.

An earth dam has a core of impermeable material, for example, fine soil or asphalt. On either side of the core there is a filter and, outside that, a shoulder. The impermeable core and filter fulfil the same function as the sealing layer and filter in a canal, while the shoulder keeps the various layers in place. The dam wall surface is exposed to enormous water pressure - some dams are more than 100 m high. The shoulder also offers protection against erosion. An alternative construction allows for a layer of concrete or asphalt upstream instead of using an impermeable core.

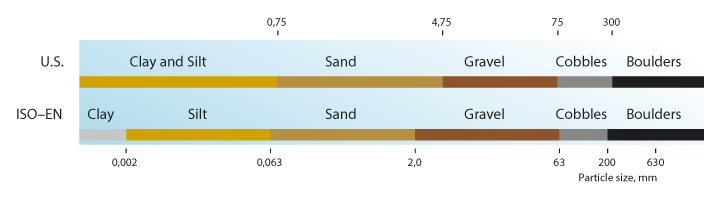

The core consists of an impermeable soil (silt and clay) or asphalt. It is important to use soil with consistent properties and that no lamination (layering) takes place during compaction.

The filter consists of sand and gravel and serves to keep the core material in place as the water forces its way through the core. It is unavoidable that water will seep through the core but it is important to keep the rate low.

The shoulder can consist of practically any type of fill material, but rock fill is the most common. It is important that the surfaces up and downstream are protected from erosion.

Materials

Both dams and canals rely on a fine grained, non-permeable core or lining to function as designed. This fine grained material needs proper support to stay in place, the core of a dam requires strong shoulders to withstand the massive water pressure, and a canal lining needs a strong base underneath as well as erosion protection on top to prevent the flowing water eroding the fine material.

Construction process

A dam site is often huge and can contain millions of cubic meters of material that must be placed in the correct layer thickness and compacted. Material than be compacted in thicker layers increases the efficiency of the construction process. Huge sites can have massive benefits from using Continuous Compaction Control that helps operators run the equipment in an efficient manner and allows full coverage of the compaction control process. This also provides documentation of the compacted surface and allows areas of lower quality to be identified and corrected quickly and economically.

Layers cross-section

Layers cross-section